1. Mutsara unoshanda

Iri bhuku rinoshanda pakugadzika kweinochinjika aluminium chain conveyor

2. Kugadzirira kusati kwaiswa

2.1 Kuisa chirongwa

2.1.1 Dzidza mifananidzo yegungano kugadzirira kuiswa

2.1.2 Iva nechokwadi chekuti maturusi anodiwa anogona kupihwa

2.1.3 Ita shuwa kuti zvese zvekushandisa uye zvikamu zvinodiwa pakuunganidza iyo conveyor system zviripo, uye tarisa rondedzero yezvikamu.

2.1.4 Ita shuwa kuti pane nzvimbo yeuriri yakakwana yekuisa iyo conveyor system

2.1.5 Tarisa uone kana pasi pekuisa nzvimbo yakati sandara, kuitira kuti tsoka dzese dzekutsigira dzigone kutsigirwa pasi pevhu.

2.2 Kuisa kutevedzana

2.2.1 Kucheka matanda ose kusvika pakureba kunodiwa mumifananidzo

2.2.2 Batanidza tsoka uye danda rechimiro

2.2.3 Isai matanda ekutakurisa uye woamisa pane yerutsigiro chimiro

2.2.4 Isa dhiraivha uye Idler unit pamagumo emutakuri

2.2.5 Edzai chikamu checheni inotakura, tarisa kuti uone kuti hapana zvipingaidzo.

2.2.6 Unganidza uye isa cheni ndiro pane conveyor

2.3 Gadziriro yezvishandiso zvekuisa

Zvishandiso zvekuisa zvinosanganisira: cheni yepini yekuisa chishandiso, hex wrench, hex wrench, pistol drill.Diagonal pliers

2.4 Zvikamu uye kugadzirira zvinhu

Standard fasteners

Slide nzungu

Square nzungu

spring nut

Kubatanidza tambo

3 Gungano

3.1 zvikamu

Iyo yakakosha conveyor chimiro inogona kukamurwa kuita zvinotevera zvikamu zvishanu mapoka

3.1.1 Chimiro chekutsigira

3.1.2 Conveyor danda, chikamu chakatwasuka uye chikamu chekukotama

3.1.3 Dhiraivha uye Idler unit

3.1.4 Flexible cheni

3.1.5 Zvimwe zvekushandisa

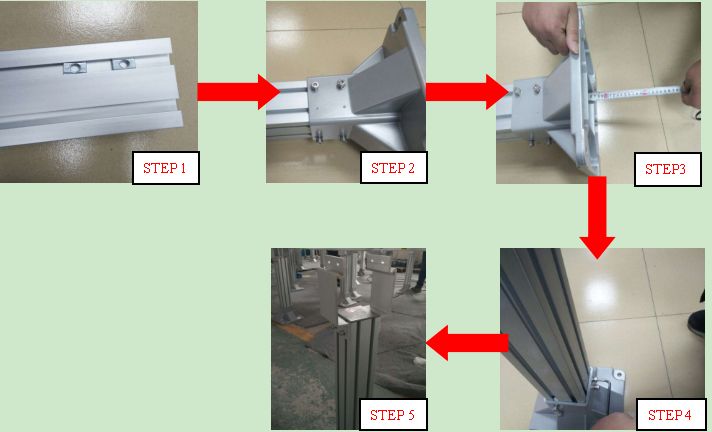

3.2 Kuisa tsoka

3.2.1 Isai chinotsvedza nati muT-slot yedanda retsigiro

3.2.2 Isa danda retsigiro mundiro yetsoka, uye gadzirisa inotsvedza nati yaiswa pamberi nemakona ehexagon socket, woisimbisa zvakasununguka.

3.3.1 Gadzirisa danda kubva pasi petsoka kusvika kuhukuru hunodiwa nedhirowa, iyo iri nyore kugadzirisa urefu mukusangana kunotevera.

3.3.2 Shandisa chipanera kusimbisa screws

3.3.3 Isa danda rekutsigira furemu nekuisa ndiro yetsoka

3.3 Kuiswa kwedanda rekutakura

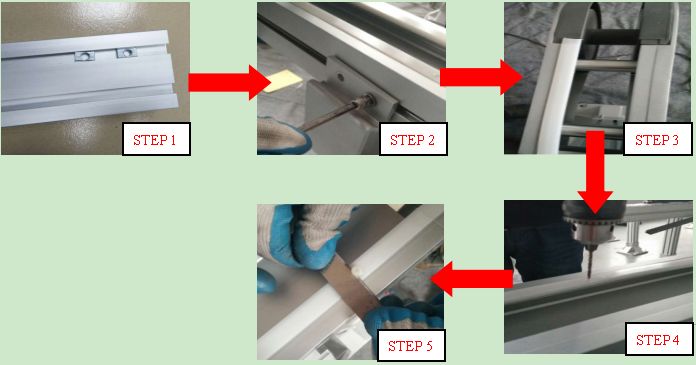

3.3.4 Isai mutserendende muT-slot

3.3.5 Tanga wagadzirisa bhureketi rekutanga nedanda rekutakura, wozokweva bhureketi rechipiri worisimbisa nema screws.

3.3.6 Kutanga kubva kudivi reIdler unit, dzvanya tambo yekupfeka uchiisa panzvimbo yekuisa

3.3.7 Kurova nekurovera pawear strip

3.3.8 Isai nati yepurasitiki wocheka chikamu chekuwedzera nebanga rekushandisa

3.4 Kuiswa uye kubviswa kwechain plate

3.4.1 Tanga kuiswa kwendiro yeketani mushure mekunge musangano wemutumbi wemidziyo wapera,.Chekutanga, bvisa ndiro yepadivi padivi peiyo idler unit, wozotora chikamu chetani chendiro, woiisa kubva kune idler unit kupinda mudanda rekutakura, uye sunda ndiro yeketani kuti imhanye nedanda rekutakura redenderedzwa.Iva nechokwadi chekuti conveyor assembly inosangana nezvinodiwa

3.4.2 Shandisa cheni yekupinza pini kupinza marata echeni munhevedzano, teerera pamire mabhero enaironi nechokunze, wodzvanya pini yesimbi mundiro yecheni kuti igare pakati.Mushure mekunge ndiro yeketani yapetwa, iise mudanda rekutakura kubva kune idler unit, teerera kune cheni ndiro Iyo nzira yekufambisa.

3.4.3 Mushure mekunge cheni ndiro yapeta panzira yekufambisa yedenderedzwa, simbisa musoro nemuswe wecheni plate kuti utevedzere mamiriro emidziyo mushure mekusangana (haifanire kunge yakasununguka kana kuti yakanyanya kusimba), simbisa hurefu hwe. iyo inodiwa cheni ndiro, uye bvisa yakawandisa cheni ndiro (disassemble Yenylon bead haikurudzirwe kushandiswa zvakare)

3.4.4 Bvisa iyo Idler sprocket uye shandisa cheni yepini yekuisa chishandiso kubatanidza cheni plate yekupedzisira kusvika kumagumo.

3.4.5 Isai Idler sprocket uye patsanurwa ndiro yeparutivi, teerera kune tambo isingapfeki iri padivi ndiro inoda kuunganidzwa panzvimbo, uye hapagone kuve nekusimudza chiitiko.

3.4.6 Kana ndiro yeketani yakatambanudzwa kana zvimwe zvikonzero zvinoda kubviswa, matanho ekuvhiya anodzokera kumashure ekugadzirisa.

Nguva yekutumira: Zvita-27-2022